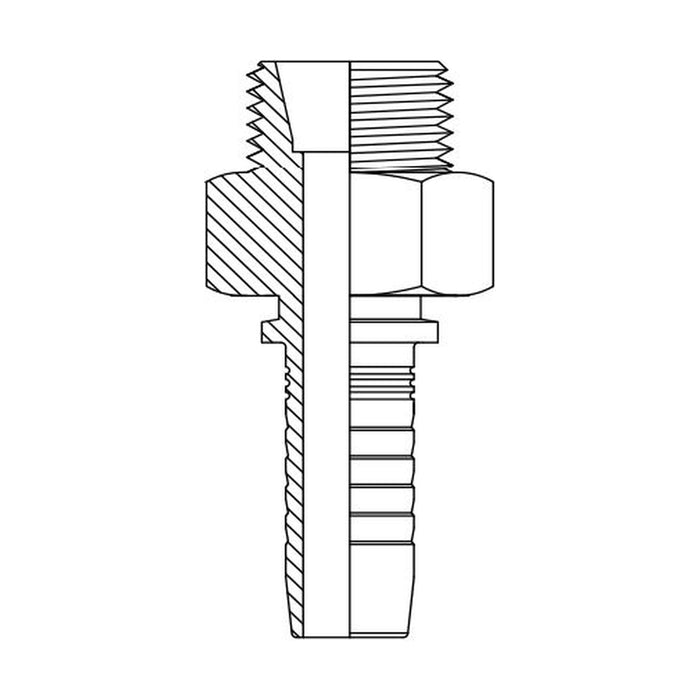

Hose Tail Barb Metric Light Male Straight

Hose Tail Barb Metric Light Male Straight – Two-Piece Hydraulic Fitting

The ENGMATTEC Two-Piece Metric Light Male Hydraulic Hose Tail with a straight design is expertly crafted for use in high-pressure hydraulic systems. Featuring Metric Light Male threads adhering to DIN standards, this fitting is compatible with a range of hydraulic hoses, including SAE (Society of Automotive Engineers) 100R1, 100R2, and thermoplastic options like SAE 100R6 and SAE 100R7.

Sizes Available:

Hose sizes: 1/4" to 1 1/2". Metric Light Male thread sizes: M12 (6L) to M52 (42L).

Design Features:

- Straight design simplifies hydraulic layouts for ease of assembly.

- Manufactured using high-quality materials for durability and corrosion resistance.

- Precision-machined for secure, leak-free connections under high-pressure conditions.

- Compatible ferrules required for assembly (sold separately).

Applications:

- Ideal for use in construction, agricultural, and industrial hydraulic systems.

- Designed for high-pressure fluid conveyance requiring Metric Light Male thread connections.

- Suitable for diverse hydraulic setups with easy field adaptability.

Performance Highlights:

- Compatible with SAE 100R1, 100R2, and thermoplastic hoses such as SAE 100R6 and SAE 100R7.

- Provides strong, leak-free connections to ensure reliable performance in demanding applications.

Machine Brands Using Metric Light Male Fittings:

- Construction Equipment: Caterpillar, Komatsu, Volvo, and JCB.

- Industrial Machinery: Hitachi, Liebherr, and Doosan.

- Agricultural Equipment: John Deere, New Holland, and Case IH.

Important Notes:

- This listing is for the hosetail only; ferrules must be purchased separately for a complete assembly.

- Use calipers or verniers for accurate measurements to ensure compatibility.

- Ensure the fitting matches the hose type and pressure rating before installation.